|

Mercedes-Benz E 400 CDI: smooth diesel power

from eight cylinders

- The most powerful V8 passenger car diesel engine

- 191 kW/260 hp output and 560 Newtonmetres of torque

- Common rail technology, bi-turbo system and water intercooling

Stuttgart,

Feb. 13, 2003 -- From the spring of 2003, the Mercedes-Benz E-Class

will be available in a version with the world’s most powerful V8

passenger car diesel engine. The bi-turbo unit with common rail direct

injection, together with other high-tech innovations, is capable of developing

191 kW/260 hp from a displacement of 3996 cubic centimetres. Through specific

detailed improvements to the engine, the charge-air cooling and the exhaust

system, the Mercedes engineers have managed to achieve an increase in

power output of 7 kW/10 hp over the V8 diesel engines in the S, M and

G-Class. Stuttgart,

Feb. 13, 2003 -- From the spring of 2003, the Mercedes-Benz E-Class

will be available in a version with the world’s most powerful V8

passenger car diesel engine. The bi-turbo unit with common rail direct

injection, together with other high-tech innovations, is capable of developing

191 kW/260 hp from a displacement of 3996 cubic centimetres. Through specific

detailed improvements to the engine, the charge-air cooling and the exhaust

system, the Mercedes engineers have managed to achieve an increase in

power output of 7 kW/10 hp over the V8 diesel engines in the S, M and

G-Class.

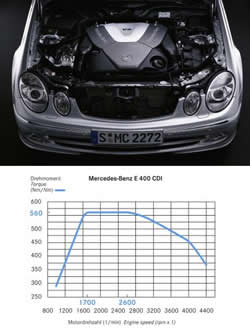

The maximum torque of 560 Newtonmetres, available between 1700 and 2600

rpm, is also among the best for a diesel-powered passenger car. As a result,

the car is capable of swift acceleration and powerful intermediate bursts

of speed: the E 400 CDI reaches 100 km/h from a standing start in just

6.9 seconds, while the figure of 6.7 seconds for its acceleration from

60 to 120 km/h truly demonstrates its remarkable tractive power.

These are new top figures for a diesel in this vehicle class. The bi-turbo

engine has demonstrated its further qualities in the fuel consumption

tests of the European test cycle. The EUDC combined consumption figure

is only 9.4 litres per 100 kilometres, thus allowing the E 400 CDI to

cover more than 850 kilometres on one 80-litre tank of fuel.

The arrival of the new top-of-the-range CDI model means that there are

now five state-of-the-art direct injection diesel engines in the Mercedes-Benz

E-Class Saloon range. Their output ranges from 90 kW/122 hp in the E 200

CDI to 191 kW/260 hp in the E 400 CDI. As well as a five-speed automatic

transmission, the standard equipment of this most powerful of diesel-powered

passenger cars includes the electronically controlled air suspension system

AIRMATIC DC (Dual Control), the four-zone luxury climate control system

THERMOTRONIC, 17-inch light-alloy wheels and speed-sensitive power steering.

Engine technology: a unique combination of diesel

innovations

The excellent performance achieved with the eight-cylinder

engine is the consequence of all the latest diesel innovations for the

Mercedes-Benz brand, combined here by the development team in Stuttgart

with a range of new developments. For instance:

- Four-valve technology

- Common rail system with pilot injection

- Throttled-intake high-pressure pump

- Bi-turbo charging with variable turbine geometry (VNT technology)

- Water-cooled intercooler

- Exhaust gas recirculation

- Electrically operated air intake throttle

- Lightweight construction with aluminium cylinder heads and crankcase

Turbocharger: electric controls for spontaneous

thrust

Principally responsible for the impressive torque and performance

development are the two exhaust gas turbochargers to the left and right

of the cylinder banks. The bi-turbo system’s electronic controls,

with dual air mass sensor, enable it to work in a synchronised fashion

and to adjust the supply of combustion air precisely to the required performance.

This is made possible above all by the variable turbine geometry on the

basis of VNT (Variable Nozzle Turbine) with electric and thus spontaneously

adjustable guide vanes controlled by mapped performance data.

The cooling of the intake air compressed by the turbochargers is undertaken

by a water-cooled intercooler attached to a special low-temperature water

cooler that is kept supplied with coolant by a separate electric circulation

pump. This lowers the air temperature by up to 100 degrees Celsius, ensuring

that the engine uses more air and can thus develop more power.

Direct

injection: common rail system with adjustable high-pressure pump Direct

injection: common rail system with adjustable high-pressure pump

Like all Mercedes-Benz CDI engines, the fuel injection system

in the new E 400 CDI works on the principle of common rail. The injection

pump has been specially developed for the eight-cylinder engine

and can be controlled by means of an intake throttle according to need

– depending on the injection pressure – ensuring that the fuel

temperature is reduced by up to 20 degrees Celsius, so re-ducing exhaust

emissions and lowering fuel consumption when compared to a conventional

system. The intake throttle, however, acts merely as a pre-control for

the high-pressure pump, with the actual injection pressure in the two

rails still being provided by the electronic engine management and the

regulating valve. A particular feature of the Mercedes-Benz CDI engines

is what is known as pilot injection. Here, too, in the eight-cylinder

units, this leads to an audible reduction in combustion noise. Just a

few milliseconds before the actual fuel injection, a small quantity of

diesel is allowed to flow into the cylinder, where it ignites, thus pre-warming

the combustion chambers. This improves conditions for the main injection

process that follows: the fuel ignites sooner, while combustion chamber

pressure, temperature and thus also combustion noise are kept at a low

level.

Cylinder heads: high cylinder charging even

in partial load range

The aluminium cylinder heads are designed to meet the particular

demands of common rail technology. The injectors are centrally located

between the four valves, thus ensuring optimum fuel distribution. The

valves are controlled by two hollow-cast camshafts per cylinder bank,

together with bucket tappets.

Spiral intake ports in the cylinder heads, one of which in each case

is optimised for swirl, the other for flow, and which are precisely matched

to the symmetrically formed combustion chambers, set the air into fast-swirling

motion and so ensure the ideal mixture of fuel and intake air in the partial-load

range. An electro-pneumatic intake port cut-out also comes into effect

in the partial-load range. By temporarily cutting off one intake port,

this increases further the swirl speed of the fuel-air mixture –

and thus the cylinder charging rate.

Exhaust gas recirculation: demand-responsive

control depending on engine load and speed

The intake system of the new V8 diesel engine also includes

an air filter with two hot-film air mass sensors installed in the engine,

which give a precise analysis of the air drawn in. These give the microcomputer

responsible for the engine management the precise data that enable it,

for example, to control the exhaust gas recirculation according to the

engine load and speed – all in the interests of lower exhaust emissions.

There are two recirculation valves for the exhaust gases – one per

cylinder bank. These are controlled electrically by a rotary magnet and

regulate the amount of exhaust gas which is recirculated, depending on

the load on the engine, in a defined ratio to the intake air. Exhaust

gases also flow through a heat exchanger, where they are further cooled.

The emissions limits of the new eight-cylinder diesel engine fall well

within the EU 3 emissions limits, not only with the help of its efficient

exhaust gas recirculation system, which contributes primarily to the reduction

of nitrogen oxide emissions, but above all thanks to its sophisticated

catalytic converter system. This consists of two exhaust-gas purifiers

located near the engine, which begin to act as oxidation catalysts very

soon after a cold start and which are responsible for reducing the level

of hydrocarbons and carbon monoxide by chemical bonding with oxygen.

Combination: balancing shaft with centrifugal

oil separator

In order to keep the dimensions as compact as possible, the

Mercedes engineers designing the V8 engine decided upon a cylinder angle

of 75 degrees, compensating the vibrations typical of this construction

concept with a balancing shaft. This is located in the space between the

two banks of cylinders and rotates at the same speed but in the opposite

direction to the camshaft. At the front end of the balancing shaft is

an oil separator, which ventilates the engine by centrifugal force.

The solid base of the V8 engine with CDI technology is formed by an aluminium

crankcase, manufactured according to a new sand-casting method. The advantage

of this is its increased strength, which has given the engineers much

more scope in terms of engineering design. For the first time, for example,

they have been able to integrate the timing case as well as the oil ducts

and returns directly into the crankcase itself. This aluminium construction

method not only improves the smoothness of the engine, but also helps

reduce its weight: the crankcase of the V8 engine, at 56.2 kilograms,

is approximately 17 per cent lighter than the comparable component in

the CDI six-cylinder unit of the E 320 CDI. The eight-cylinder engine,

with all its ancillary components, weighs a total of 245 kilos and is

thus the lightest diesel unit in this displacement category.

|

Mercedes-Benz E 400 CDI

|

| Engine |

| No. of cylinders/arrangement |

8/V, 4 valves per cylinder

|

| Total displacement (cc) |

3996 |

| Bore x stroke (mm) |

86.0 x 86.0 |

| Rated output (kW/hp) |

191/260 at 4000 rpm |

| Rated torque (Nm) |

560 at 1700 – 2600 rpm |

| Compression ratio |

18.5 : 1 |

| Mixture formation |

High-pressure injection, common rail technology,

2 exhaust gas turbochargers, electronic EDC engine management |

| Transmission |

| Transmission |

5-speed automatic with touch shift

|

| Gear ratios |

Final |

2.47

|

| 1st |

3.60

|

| 2nd |

2.19

|

| 3rd |

1.41

|

| 4th |

1.00

|

| 5th |

0.83

|

| Reverse |

3.17 / 1.93

|

| Dimensions |

| Wheelbase |

2854 mm

|

| Track |

Front |

1567 mm

|

| Rear |

1560 mm

|

| Length – overall |

4818 mm

|

| Width – overall |

1822 mm

|

| Height – overall |

1431 mm

|

| Turning circle |

11.4 m

|

| Max. luggage capacity* |

530 l

|

| Curb weight |

1835 kg

|

| Payload |

525 kg

|

| Max. GVW |

2360 kg

|

| Tank capacity/inc. reserve |

80/9 l

|

| *acc. to German VDA method |

| Performance

and consumption |

| Acceleration 0-100 km/h |

6.9 seconds

|

| Top speed |

250** km/h

|

| EUDC combined fuel consumption |

9.4

|

| **electronically limited |

Although New-Cars.com checks with auto manufacturers and their representatives

to confirm the accuracy of the data, it makes no guarantee or warranty,

either expressed or implied with respect to the data presented here. All

specifications, prices and equipment are subject to change without notice.

New-Cars.com Home

- News Archives - Car

Reviews - New

Car Price Quote - Privacy Policy

- Contact Us

Copyright © 2002 New-Cars.com

|